Cautions regarding handling products

Cautions regarding handling products

- Do not place products near open flame. Doing so may result in fire or deformation of the product.

- Do not use products in an oven or a grill. Doing so may result in fire or deformation of the product.

- Do not place hot items such as freshly fried food into products. Doing so may cause deformation and holes in the product.

- Avoid storing products in direct sunlight or in hot and humid places. In particular, A-PET has low heat resistance and may be deformed by heat.

- Take care when handling containers as the edges may cause cuts to fingers.

- Do not press on containers with any force. Doing so may cause damage.

- Do not store products in a damaged plastic bag as dust and particles may adhere to them. After opening, store products in a closable plastic bag.

- Do not overly stack products when storing them as the stack may fall over.

- Do not reuse used containers as hygiene related problems may occur.

- When disposing of products, follow the applicable regulations and ordinances.

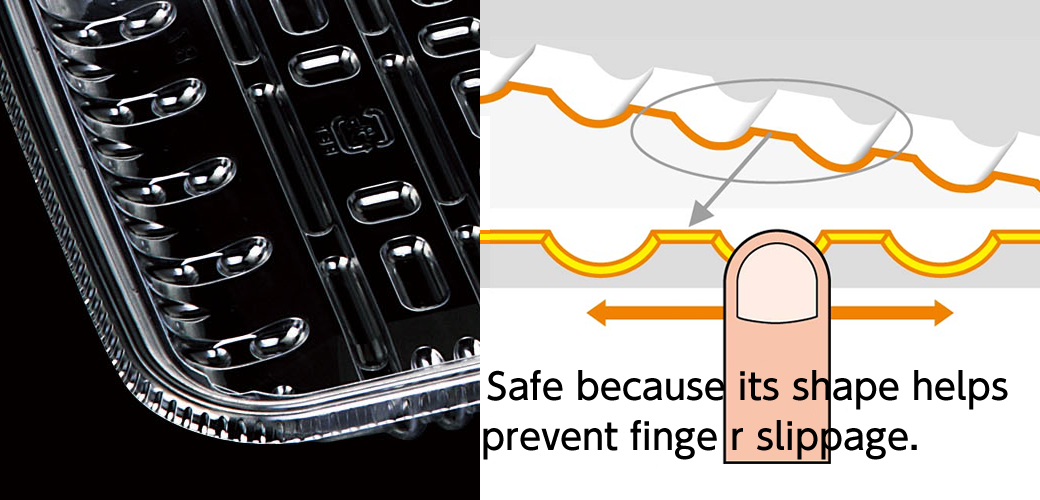

Safety Edge is shaped for safety to reduce a possibility of cuts to fingers when working with products

FPCO's Safety Edge containers are formed with special edges on the lids and containers so that the people who use them can do so more safely.

Characteristics of each type of material and cautions regarding handling

| Material | Heat resistance | Suitability for microwave ovens | Cold resistance | Oil resistance | Resistance to PVC wrap |

|---|---|---|---|---|---|

| Foamed polystyrene | 80℃ | × | ○ | × | ○ |

| This material has superior humidity retention and insulation characteristics, and has good formability for rigidity, and has a wide range of applications for containers used at normal temperatures. | |||||

| Eco Tray (foamed polystyrene) |

80℃ | × | ○ | × | ○ |

| This material has the superior humidity retention and insulation characteristics and the good formability for rigidity of foamed polystyrene, Eco Tray (TM) is manufactured by the FPCO "Tray to Tray (TM)" recycling method with a material from used trays collected at supermarkets. | |||||

| Multi FP (heat & cold resistant polystyrene) |

110℃ | ○ | ○ | ○ | ○ |

| This is a new product with both heat and cold resistance. It is a foamed material, so has superior insulation characteristics, and can be used for a wide range of applications from freezing to heating in a microwave oven. | |||||

| Multi SD | 110℃ | ○ | △ | ○ | ○ |

| This is a non-foamed material born by modifying Multi FP (TM). It has excellent plasticity for forming sharp shapes and is very suitable for use in microwave ovens. | |||||

| HI Black (heat & oil resistant polystyrene) |

110℃ | ○ | × | ○ | ○ |

| Heat resistance was improved by modifying polystyrene. This material can be used for heat resistant food containers which offer a sense of quality through colors such as jet black. | |||||

| Exstar (heat & oil resistant foamed polystyrene) |

110℃ | ○ | △ | ○ | ○ |

| Heat resistance was improved by modifying polystyrene. With its excellent heat resistance combined with its unique soft feeling, this material can be used for heat resistant food containers which offer a sense of quality. | |||||

| Histar / New Histar (heat & oil resistant foamed polypropylene) |

130℃ | ○ | × | ○ | ○ |

| With its superior heat resistance combined with its unique soft feeling, this material can be used for heat resistant food containers which offer a sense of quality. | |||||

| HIPS (non-foamed polystyrene) |

90℃ | × | △ | × | × |

| With excellent rigidity and good plasticity, this material can be used for containers used at normal temperatures. | |||||

| WU (microwaveable wooden-feel container) |

130℃ | ○ | × | ○ | ○ |

| By using heat resistant material for the interior section, we realized a product which can be heated in microwave ovens. | |||||

| PP with talc filler (polypropylene with talc filler) |

130℃ | ○ | × | ○ | ○ |

| This material has a heat resistance level to 130℃ and suitable for microwaveable use for bento lunch boxes and pre-cooked foods. | |||||

| PP (polypropylene) |

110℃ | ○ | × | ○ | ○ |

| With its superior heat resistance, this material can be used for inner packaging, lids, microwaveable containers, and heat resistant containers. | |||||

| A-PET (amorphous polyethylene terephthalate) |

60℃ | × | × | ○ | ○ |

| With transparency combined with oil resistance, this material is used for applications such as salad and pre-cooked food containers. | |||||

| Eco APET | 60℃ | × | × | ○ | ○ |

| Eco A-PET (TM) containers are born-again transparent containers made from transparent containers and PET bottles collected at supermarkets. | |||||

| OPS (bi-axially oriented polystyrene) |

80℃ | △ | ○ | × | × |

| This material is very transparent so is mainly used as the material for lids and in the SA and SA-400 series. | |||||

| O-PET (bi-axially oriented PET) |

80℃ | △ | ○ | ○ | ○ |

| This world first material is longitudinally and laterally stretched PET which retains its conventional properties of oil resistance and transparency, but also realizes heat resistance of 80℃ , similar to OPS. | |||||

| Suitability for microwave ovens: | The contents of a container can be heated in a microwave oven, but please do not use such containers for preparing food. |

|---|---|

| Cold resistance: | The level of cold resistance is evaluated by comparing different materials in accordance with our internal standards. Depending on the temperature conditions and size of a shock, damage may be caused to a product. Please test products under the actual conditions of use in advance. |

| Oil resistance: | Terpene oils found in the skin of citrus fruits, such as lemon, and MCT oils may cause polystyrene-based containers to become brittle and degrade. (Note 1) Please see below for further information on MCT oils. |

| Resistance to PVC wrap: | There is a risk that polystyrene-based containers may become brittle due to the plasticizers used in the PVC wraps. Take care when using PVC wraps. (Note 2) Please see below for further information on plasticizers used in the PVC wraps. |

(Note 1) About MCT oils

MCT oils are mainly composed of the medium-chain fatty acid triglyceride, and are widely used by food processing manufacturers as detaching agents, glossing or polishing agents, and lubricants for machines that process food.

Examples:

●Detaching agents... For increasing workability for foods such as candies, caramels, and gum

●Glossing or polishing agents... For polishing or glossing for foods such as rice and fried noodle

●Lubricants and appropriate slipperiness... For preventing food adhering to processing machines and preventing stickiness

Note that these MCT oils aggressively attack polystyrene, and if used with polystyrene-based containers MCT oils may cause the containers to become brittle resulting in breakage.

(Note 2) PVC wraps (plasticizers)

PVC itself is a hard resin (plastic), and plasticizers are used in PVC wraps to enable them to be used as soft wraps that stretch. Note that these plasticizers aggressively attack polystyrene-based (OPS, HIPS) containers, and may cause containers to become brittle resulting in breakage.

Be sure to test suitability for microwave ovens by placing food into containers and testing in a microwave oven.

Microwave ovens heat foods by electromagnetic waves (high frequencies), but plastics are unaffected by high frequencies so the containers themselves do not heat up. Containers are heated indirectly by the heat from the heated food.

Cautions related to using microwaveable containers

1. Do not use containers in ovens or grills

2. Do not let containers boil dry. Damage may be caused to the microwave oven.

3. Use containers after removing lids. Lid may pop off if it does not have a ventilation hole.

4.

Regarding the heating time in microwave ovens, foods with a high salt or fat content or low water content may become extremely hot if heated for a long time. Be sure to specify the heating time after performing actual tests.

Examples: pickles, salted seaweed.

Cautions and requests for “vapor deposited aluminum” products

Product examples

| Deluxe/silver | Grace silver | Gold | Others | ||

|---|---|---|---|---|---|

| Horyo A | BS | Hirafune | Platter Maru | Tiara | WK |

| FL Oogiori | Tiara | Hyoga (sashimi) | MSF-200 | Hors d'oeuvres | |

| FU | Hors d'oeuvres | Isobune | Hirafune moridai | ||

| Morizara | MSF |

Hazara (sashimi) |

Mifune | ||

| MSF-200 | Platter Maru | FU | Toyoyama | ||

| MSF-A/Y | Kasane Oke | Moriyama | MV | ||

| MSF-round | Oogiori S | Morizara | Kakukozara | ||

| MV | Hors d'oeuvre | Maizarabashi | |||

| Shabu-shabu | MSF | ||||

●Cautions

The above series of products are containers that have a layer of aluminum vapor deposited on the underside of the surface laminate. Called “vapor deposited aluminum containers” below.

Vapor deposited aluminum containers cannot be used in microwave ovens.

If a vapor deposited aluminum container is used in a microwave oven, sparks will be created, which may result in fire and damage to the microwave oven.

When selling foods in vapor deposited aluminum containers, be sure to caution consumers that such containers cannot be used in microwave ovens by using POP or stickers.

Also note that if vapor deposited aluminum containers are inspected using a metal detector, the metal detector may detect the metal.