Nationwide infrastructure network

Manufacturing, distribution, and recycling network that covers all of Japan

Maintain a manufacturing supply structure

in the outlying areas of places

of consumption nationwide

With expansion of the market,

manufacturing plants are located nationwide

to ensure a stable product supply.

- Hokkaido Plant (Ishikari-shi, Hokkaido)

- Yamagata Plant (Sagae-shi, Yamagata)

- Kanto Plant (Yachiyo-machi, Ibaraki)

- Kanto Yachiyo Plant (Yachiyo-machi, Ibaraki)

- Kanto Shimodate Plant (Chikusei-shi, Ibaraki)

- Chikusei Plant (Chikusei-shi, Ibaraki)

- Kanto Tsukuba Plant (Shimotsuma-shi, Ibaraki)

- Chubu Plant (Wanouchi-cho, Gifu)

- Kinki Kameoka Plant (Kameoka-shi, Kyoto)

- Kasaoka Plant (Kasaoka-shi, Okayama)

- Fukuyama Plant (Fukuyama-shi, Hiroshima)

- Kannabe Plant (Fukuyama-shi, Hiroshima)

- Shikoku Plant (Nankoku-shi, Kochi)

- Kyushu Plant (Yoshinogari-cho, Saga)

- Nango Plant (Nichinan-shi, Miyazaki)

- Kagoshima Plant (Kagoshima-shi, Kagoshima)

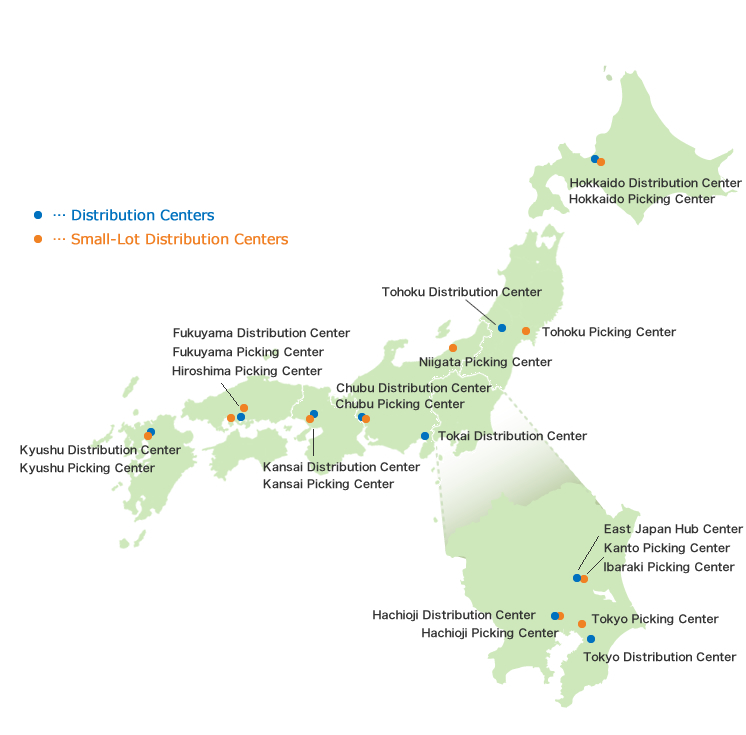

Build a distribution network

that fully covers all of Japan

Realize efficient distribution and strengthen the handling of risks such as natural disasters.

Stable supply at optimum distribution costs for customers nationwide is realized.

- Distribution Centers

- Hokkaido Distribution Center (Ishikari-shi, Hokkaido)

- Tohoku Distribution Center (Sagae-shi, Yamagata)

- Kanto Hub Center (Yachiyo-machi, Ibaraki)

- Tokyo Distribution Center (Funabashi-shi, Chiba)

- Hachioji Distribution Center (Hachioji-shi, Tokyo)

- Tokai Distribution Center (Nagaizumi-cho, Shizuoka)

- Chubu Distribution Center (Wanouchi-cho, Gifu)

- Kansai Distribution Center (Kobe-shi, Hyogo)

- Fukuyama Distribution Center (Fukuyama-shi, Hiroshima)

- Kyushu Distribution Center (Yoshinogari-cho, Saga)

- Small-Lot Distribution Centers

- Hokkaido Picking Center (Ishikari-shi, Hokkaido)

- Tohoku Picking Center (Ohira-mura, Miyagi)

- Kanto Picking Center (Yachiyo-machi, Ibaraki)

- Hachioji Picking Center (Hachioji-shi, Tokyo)

- Tokyo Picking Center (Koto-ku, Tokyo)

- Niigata Picking Center (Nagaoka-shi, Niigata)

- Chubu Picking Center (Wanouchi-cho, Gifu)

- Kansai Picking Center (Kobe-shi, Hyogo)

- Fukuyama Picking Center (Fukuyama-shi, Hiroshima)

- Hiroshima Picking Center (Hatsukaichi-shi, Hiroshima)

- Kyushu Picking Center (Yoshinogari-cho, Saga)

Realize domestic circular recycling

of above ground resources

Recycling business where the environment and employment opportunities

for the disabled are integrated is developed nationwide.

- Recycling Sorting Plants

- Hokkaido Sorting Plant (Ishikari-shi, Hokkaido)

- Yamagata Sorting Plant (Sagae-shi, Yamagata)

- Kanto Sorting Plant (Yachiyo-machi, Ibaraki)

- Tokai Sorting Plant (Nagaizumi-cho, Shizuoka)

- Matsumoto Sorting Plant (Matsumoto-shi, Nagano)

- Kanazawa Sorting Plant (Kanazawa-shi, Ishikawa)

- Gifu Sorting Plant (Wanouchi-cho, Gifu)

- Nishinomiya Sorting Plant (Nishinomiya-shi, Hyogo)

- Fukuyama Sorting Plant (Fukuyama-shi, Hiroshima)

- Saga Sorting Plant (Kanzaki-shi, Saga)

- Recycling Plants

- Kanto Recycling Plant (Yachiyo-machi, Ibaraki)

- Chubu Recycling Plant (Wanouchi-cho, Gifu)

- Fukuyama Recycling Plant (Fukuyama-shi, Hiroshima)

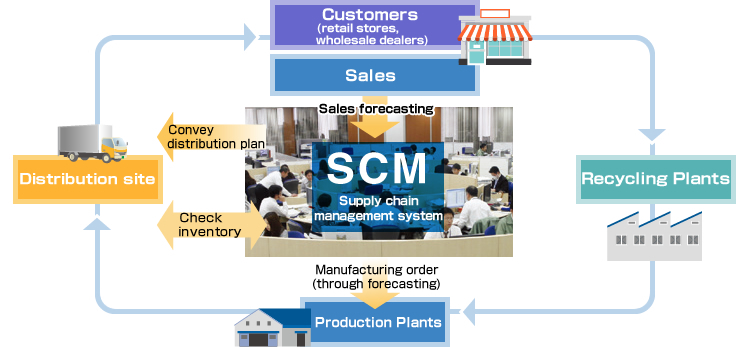

Installation of an SCM system that realizes optimization of total cost

Along with building a nationwide infrastructure network, FPCO Group has also installed an SCM (supply chain management) system. The SCM system draws up manufacturing schedules and centrally manages materials procurement planning, product supply planning, and inventory planning, based on the sales plans of sales departments. Mold tools which are essential in manufacturing are moved to manufacturing plants in a planned manner in accordance with demand. By operating this system, we are realizing overall optimized distribution costs through expanded manufacturing at points of demand where the benefits of cost reductions are large thus enabling effective distribution to delivery points.

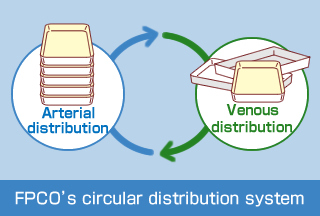

Circular recycling system using the FPCO method

FP Corporation implemented initiatives to reduce the load on the environment by collecting used trays very early on. If trucks that travel to delivery points are "arteries", then trucks that collect used trays are "veins". By building a venous distribution system trucks that travel to delivery points then collect used trays, we realize resource savings, reduced waste, and better energy efficiency.

Distribution sites located nationwide

As a manufacturer of food containers, FPCO is proud of its largest network of distribution sites in Japan. We built a framework for flexibly operating space and human resources on a consistent basis and are carrying out the distribution of packing materials and consumables required by packing materials wholesalers and supermarkets, centered on food tray containers. In addition, we have also prepared a small lot distribution center function for performing small lot shipments to stores.

Picking system

FPCO not only carries out product shipments in units of cases, but also have a system to carry picking service to deliver in small lots. This makes it possible to pack and ship packing materials and consumables procured from manufacturers, such as food containers and stickers, to individual shops and departments. We carry out picking in accordance with the customer's needs to deliver the optimum amount.