Climate Change and Energy Use

Climate Change

FPCO regards climate change as an environmental issue that affects business activities. To realize a low-carbon society, we will reduce CO2 emissions by promoting initiatives for efficient energy use and reduction of energy consumption in cooperation with our stakeholders, including suppliers and customers to whom products or goods are sold.

Information disclosures based on the TCFD recommendations

FP Corporation indicated its support for the recommendations of the Task Force on Climate-Related Financial Disclosures (TCFD) in March 2022, and has made disclosures based on the TCFD recommendations.

CO2 emission reduction targets

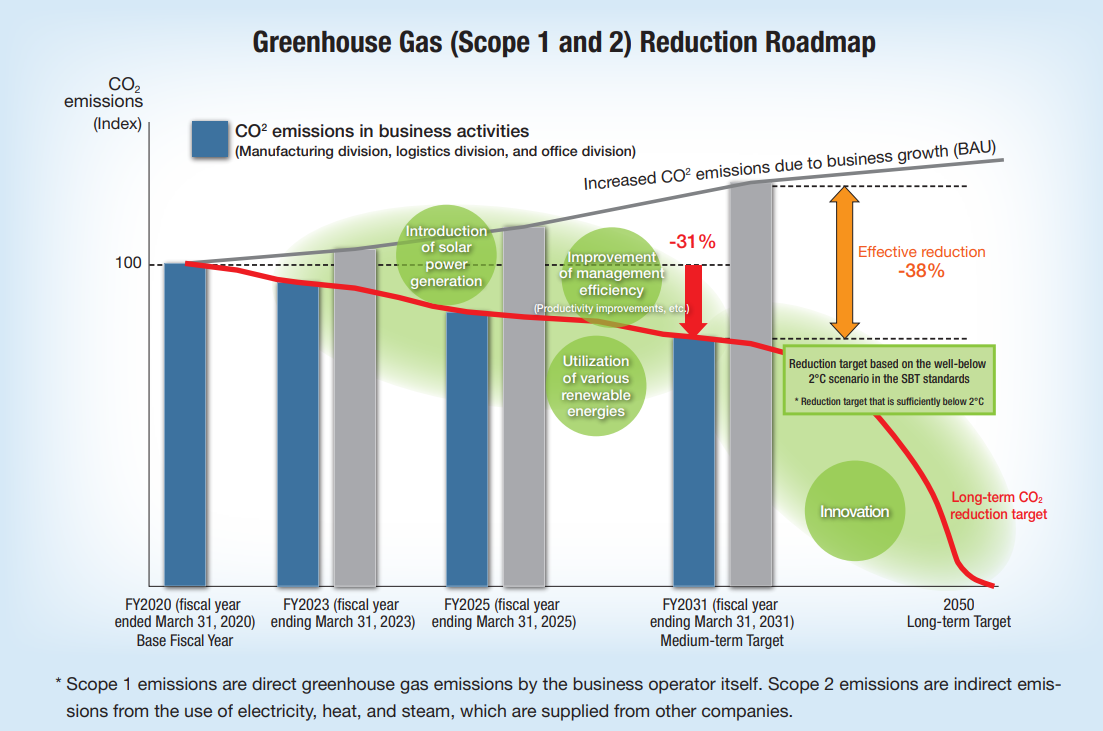

We have developed medium and long-term targets for CO2 emission reductions from the perspective of sustainability, aimed at realizing a decarbonized society. As new target values, we aim to reduce CO2 emissions (Scope 1 and 2) by 31% by the fiscal year ending March 31, 2031, and achieve zero effective CO2 emissions (Scope 1 and 2) by FY2050.

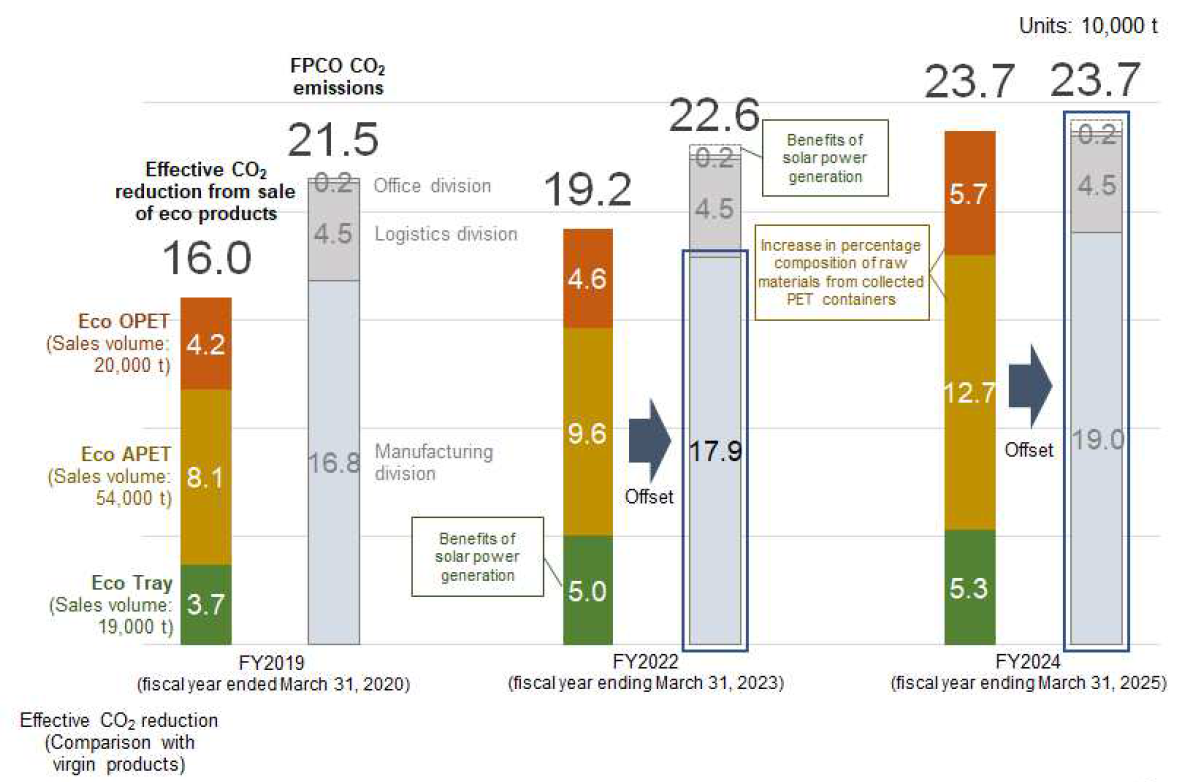

FPCO Carbon Offsetting Declaration Through Recycling

In February 2021, FP Corporation formulated a carbon offset declaration to balance CO2 emission reductions due to the sale of eco-friendly products and CO2 emissions from its own business activities.

Efforts to Reduce CO2 Emissions and Energy Usage

Sales of Eco-friendly Products

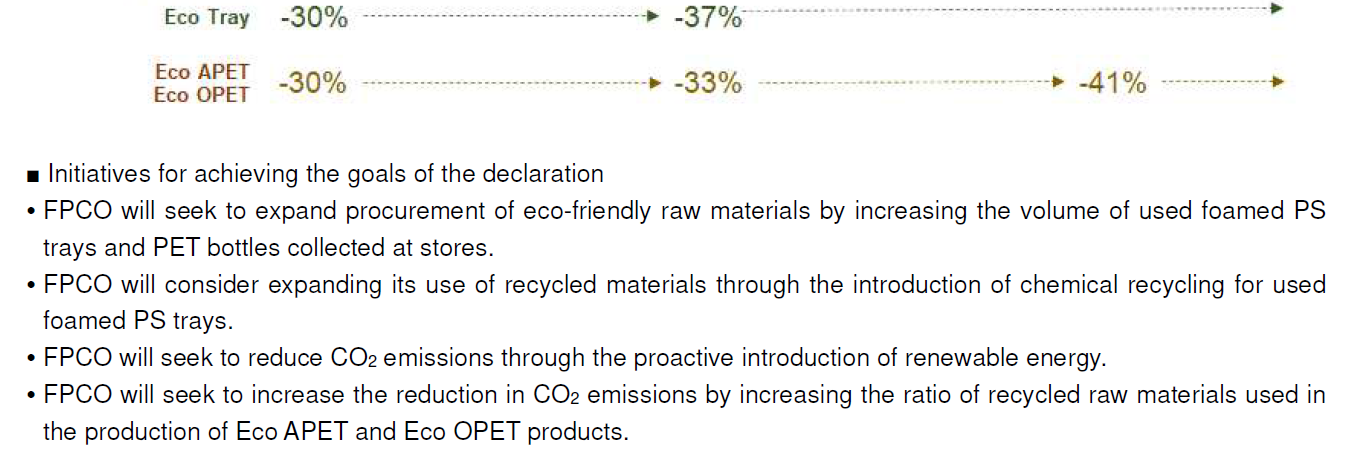

The sale of "eco-friendly products" with a CO2 emission reduction effect of 30% have the effect of reducing CO2 emissions throughout the entire supply chain.

In the fiscal year ended March 31, 2021, there was a reduction effect of approximately 170,000 tons of CO2.

| FY2019 | FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|

| Eco-friendly Products* as a Percentage of Total Sales |

41.4% | 45.7% | 45.0% | 44.0% |

* Eco Tray, Eco APET and Eco OPET product sales as a percentage of total product units sold

Use of Life Cycle Assessment

We conduct lifecycle assessments of our products so that we know their environmental impact. As a result of these analyses, we have found that our eco-friendly products use recycled materials which reduces the use of new petrochemical resources effectively reduce CO2 emissions by 30% compared to petrochemical-derived products.

However, it was revealed that the CO2 reduction effect of products containing 25% biomass plastics is only 5% to 8%. This confirms the superiority of our eco-friendly products made through FPCO Method Recycling. Lifecycle assessment enables us to provide persuasive proposals to customers. We also use the assessment to develop our eco-friendly product series and other environmentally friendly products.

Introduction of Solar Power Generating Facilities

In March 2022, we began solar power generation in the Kanto area.

In the future, we have plans to roll out solar power generation facilities to the Chubu and Kansai areas as well, and when operation goes live in both of these areas, we expand the Eco Tray CO2 reduction effects to rise from 30% to 37%.

Introduction of Energy-saving Equipment

For the purpose of reducing our energy consumption, the FPCO Group takes actions that serve this purpose, including accelerating the replacement of conventional light sources with LEDs and introducing high efficiency equipment through the scrap-and-build method.

We have also pursued the introduction of corporate PPA at recycling plants and will increase the use of renewable energies.

<Change in Amount Invested in Energy-saving Equipment>

| FY2019 | FY2020 | FY2021 |

|---|---|---|

| 177,171 thousand yen | 224,842 thousand yen | 49,920 thousand yen |

<Actual Energy Consumption>

| FY2019 |

FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|

| Energy consumption (in thousands of GJ) |

3,778 | 3,854 | 3,996 | 4,132 |

| Energy consumption rate (kJ/number of trays) |

160 | 158 | 152 | 158 |

Activities of Each Working Group Under FP Corporation Eco Action 2.0

Working groups (WGs) in each of the product, production, logistics, sales and office sectors will set their own targets and implement efforts aimed at solving social issues such as climate-related challenges.

Joint Activities With External Groups

FP Corporation is a member of an industry group known as the Japan Plastics Industry Federation (JPIF). Through JPIF, we share environmental issues in the domestic plastics industry and promote initiatives that will lead to solutions. We are also a member of the Climate Change Initiative, and vow to stand on the front lines of challenges to realize a decarbonized society.

In addition, we support Japan's climate-related laws, namely the Energy Saving Act and Global Warming Countermeasures Act, report to government bodies on our energy usage, energy-saving target achievement status and greenhouse gas emissions once a year, and will continue to implement initiatives aimed at meeting environmental targets.